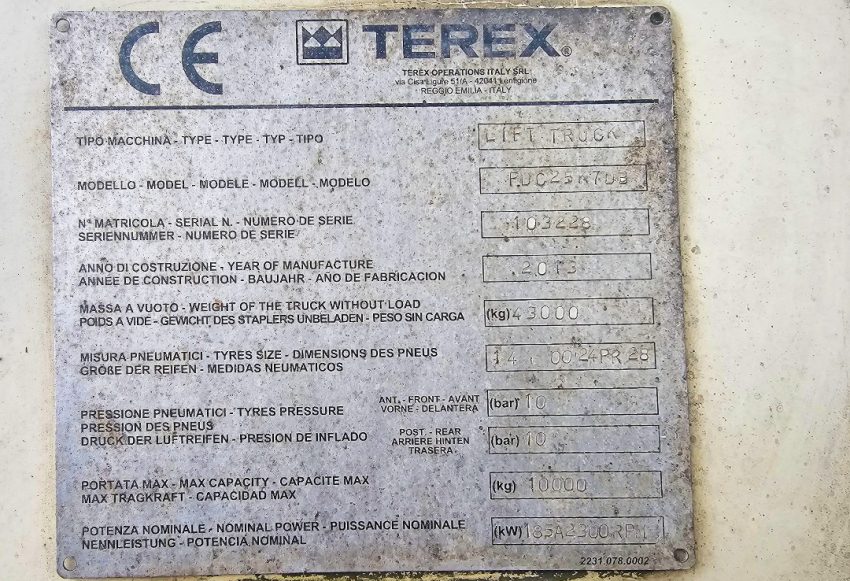

Terex FDC25K7DB Empty Container Handler – Specifications & Performance Overview

Used Terex Empty Container Handler

- Lift Capacity: 10 tons

- Stacking Height: 2‑over‑7

- Engine: Volvo TAD762VE – 185 kW, Tier 3

- Transmission: Dana TE17 / ZF 3WG211

- Axles: Kessler D81 (19.8:1)

- Brakes: Wet disc, maintenance‑free

- Cabin: Ergonomic + Logitex control system

Terex FDC25K7DB – Dual Box Empty Container Handler

About the Machine

The Terex FDC25K7DB is a heavy‑duty Empty Container Handler built for ports and logistics yards that demand high efficiency.

Its Double Box Spreader lifts two containers (20’ or 40’) at once, with a 10‑ton capacity and stacking up to 2‑over‑7 — a serious advantage in space‑limited container yards.

Powered by a Volvo TAD762VE diesel engine (185 kW, Tier 3) and smooth Dana/ZF transmission, it offers reliability, strength, and consistent performance shift after shift.

Solving Real‑World Handling Challenges

In busy terminals, empty container moves often create bottlenecks — too many trips, wasted fuel, and lost time.

This model cuts that in half. With the dual‑box capability, operators handle twice the load in one move – meaning less congestion, faster stacking, and fewer operating hours on each unit.

Designed with Your Operators in Mind

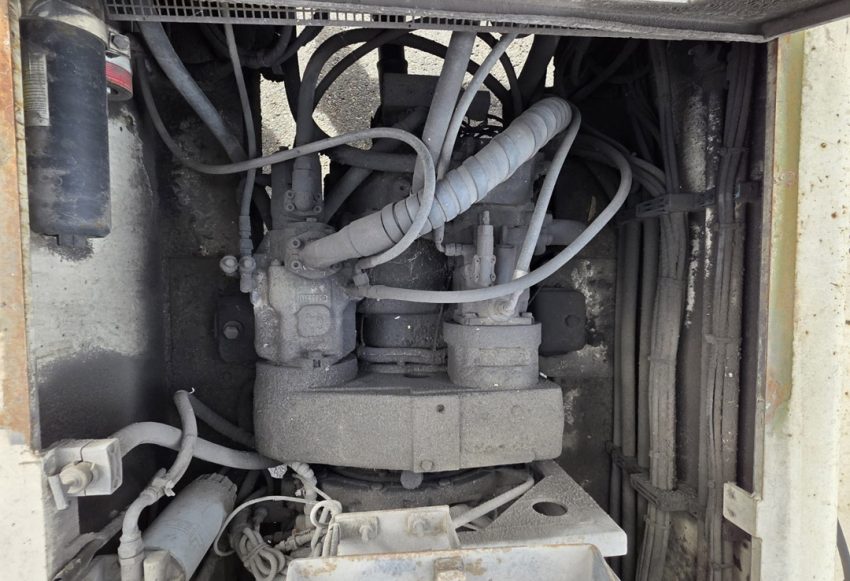

Every yard manager wants a unit that’s strong but low‑maintenance.

No one wants to stop work because of overheating hydraulics or brake issues.

Operators need comfort, visibility, and full control inside the cabin — not distraction or fatigue.

That’s where the FDC25K7DB makes a difference: wet‑disc brakes last longer with zero service downtime, and the Logitex display system keeps all key parameters visible — fuel, temperature, RPM, pressure, and faults — for complete assurance on the job.

Proven Results that Drive Efficiency

Once in operation, workflow becomes smoother:

- Yard traffic decreases and turnaround time improves.

- You save up to 50 % in movements and fuel.

- Daily throughput rises without adding more machines or manpower.

- And your operators? They end their shifts less tired and more focused.

The result is a more efficient yard, lower costs, and peace of mind — knowing your equipment works as hard as your business does.